3H VINACOM HA-5010 is a silane cross-linkable polyethylene compound for low voltage electrical wire and cable insulation. Both the grafting and wire coating process are performed in one single step in the usual wire and cable production extruder for polyethylene and cross-linking takes place through a reaction involving water vapor after being extruded.

Difficulty in maintaining dimensional accuracy during cross-linking is avoided because the temperature of cross-linking is below the crystalline melting point of the polymer.

Therefore, 3H VINACOM XLPE HA-5010 allow cross-linked polyethylene wire and cable without the need for much capital in special equipment like peroxide or radiation cross-linking.

HA-5010 SA is suitable for below 10 kva or low voltage cables complying with the standard of IEC 60502 or TCVN 5935.

ELECTRICAL PROPERTIES

| Property | Test method | Unit | Standard | Value |

| Dielectric Constant, 1KHz | ASTM D 150 | 2.3 | 2.3 | |

| Dissipation Factor, 60 Hz | ASTM D 150 | 0.00025 | 0.00025 |

PHYSICAL PROPERTIES

|

Property

|

Test method | Unit | Standard | Value |

|

Density at 23%

|

ISO 1183 | g/cm3 | 0.92 | 0.92 -0.94 |

| Tensile strength |

IEC 60502 TCVN 5935 |

g/mm2 |

1.25 |

1.95 |

| Elongation at break |

IEC 60502 TCVN 5935 |

% |

200 |

620 |

|

After aging (136°C x 168Hrs) Retention of Tensile strength |

IEC 60502 TCVN 5935 |

% |

80 |

95 |

|

After aging (136°C x 168Hrs) Retention of Elongation break |

IEC 60502 TCVN 5935 |

% |

80 |

90 |

| HOT (200oC 0.2 Mpa) |

IEC 60502 TCVN 5935 |

% |

175 |

95 |

| SET(200oC 0.2 Mpa) |

IEC 60502 TCVN 5935 |

% |

15 |

5.0 |

| Shrinkage |

IEC 60502 TCVN 7447:1998 |

% |

4 |

0.0-2.5 |

| VOLUME RESISTIVITY at 20°C |

IEC 60502 TCVN 5935 |

Ω.cm |

1.0 x 1012 |

1.0 x 1015 |

SECTION 1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

Chemical name: Silane Crosslinkable Polyethylene Compound

Grade: HA-5010 SA

Company identification

Manufacturer: 3H VINACOM CO., LTD

Address: Tien Son IP, Tien Du, Bac Ninh, Viet Nam

Telephone & Fax : Tel 84 241 3714 202 , Fax: 84 241 3714 201

Issue Date: 2012-07

SECTION 2. COMPOSITION, INFORMATION ON INGREDIENTS

Chemical name: LLDPE CAS No: 9002-88-4; contents 98.0%

Chemical name: Vinyltrimethoxysilane CAS No.: 2768-02-7; Peroxide CAS No.:80-43-3;

Dibutylin CAS No.:77-58-7; Antioxidant CAS No.: 6693-19-8: Mixed contents: 2.0%

EINECS No: Unlisted

SECTION 3. HAZARDS INDENTIFICATION

Appearance: White

Cancer suspect agent.

Target Organs : None

Potential Health Effects

The toxicological properties of this material have not been investigated.

Use appropriated procedures to prevent opportunities for direct contact

With the skin or eyes and to prevent inhalation.

SECTION 4. FIRST AID MEASURES

Eyes:

Immediately flush eyes with plenty of water for at least 15 minutes

Occasionally lifting the upper and lower lids.

Skin:

Flush skin with plenty of soap and water for at list 15 minutes

While removing contaminated clothing and shoes.

Ingestion:

Do Not induce vomiting. Allow the victim to rinse his mouth and then

to drink 2-4 cupfuls of water, and seek medical advice.

Inhalation:

Remove from exposure to fresh air immediately.

Notes to Physician:

Treat symptomatically and supportively

SECTION 5. FIRE FIGHTING MEASURES

1) General Information :

As in any fire, wear a self-contain breathing apparatus in pressure-demand,

MSHN/NIOSH (approved or equivalent), and full protective gear. During a fire,

irritating and highly toxic gases may be generated by thermal decomposition or

combustion.

2) Extinguishing Media :

In case of fire, use water, dry chemical, chemical foam, or alcohol-resistant foam.

3) Auto ignition Temperature : Not Available

4) Flash Point : > 250 deg C (>484.6 deg F)

5) NFPA Rating: Not published

6) Explosion Limits, Lower : Not available

Upper : Not available

SECTION 6. ACCIDENTAL RELEASE MEASURES

1) General Information

Use proper personal protective equipment as indicated in Section 8

2) Spills/Leaks :

Clean up spills immediately, observing precautions in the protective equipment section.

Sweep up, and then place into a suitable container for disposal.

SECTION 7. HANDLING AND STORAGE

1) Handling :

Wash thoroughly after handling. Remove contaminated clothing and wash before reuse.

Avoid contact with eyes, skin, and clothing. Avoid ingestion and inhalation.

2) Storage :

Store in a cool, dry place. Keep container closed when not in use.

SECTION 8. EXPOSURE CONTROLS, PERSONAL PROTECTION

1) Engineering controls :

Use adequate general or local exhaust ventilation to keep airborne concentrations below

the permissible exposure limits. Use process enclosure, local exhaust ventilation,

or other engineering controls to control airborne levels.

2) Exposure limits :

(1) Chemical Name : Silane Crosslinkable Polyethylene Compound (HA-5010 XLPE)

(2) ACGIH :

None listed

(3) NIOSH :

None listed

(4) OSHA-Final PELs :

None listed

3) OSHA Vacated VELs :

Low Density Polyethylene-No OSHA Vacated PELs are listed for this chemical

4) Personal Protective Equipment :

1. Eyes :

Wear safety glasses and chemical goggles if splashing is possible

2. Skin :

Wear appropriate protective gloves and clothing to prevent skin exposure.

3. Clothing :

Wear appropriate protective clothing to minimize contact with skin.

4. Respirators :

Wear a NIOSH/MSHA approved pressure mode with an emergency escape

provisions.

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

(1) Physical State : Not Available

(2) Appearance : White

(3) Odor : None reported

(4) pH : Not available

(5) Vapor Pressure : Not available

(6) Vapor Density : Not available

(7) Evaporation Rate : Not available

(8) Viscosity : Not available

(9) Boiling Point : Not available

(10) Melting Point : 105 ~ 130deg C

(11) Decomposition Temperature : Not available

(12) Solubility : Insoluble in organic solvent (20°C)

(13) Specific Gravity/Density : 0.910 ~ 0.930

(14) Molecular Formula : Not available

(15) Molecular Weight : Not available

SECTION 10. STABILITY AND REACTIVITY

1) Chemical stability:

Stable under normal temperature and pressures.

2) Conditions to Avoid:

Incompatible materials, strong oxidants.

3) Incompatibilities with Other Materials:

Strong oxidizing agents.

4) Hazardous Decomposition Product:

Carbon monoxide, irritating and toxic fumes and gages, carbon dioxide.

5) Hazardous Polymerization:

Has not been reported.

SECTION 11. TOXICOLOGICAL INFORMATION

1) RTECS No.

CAS No. 9002-88-4

2) LD 50/LC 50:

CAS No. 9002-88-4 : Inhalation, mouse : LC50 = 12 fm/m3/30M.

SECTION 12. ECOLOGICAL INFORMATION

Ecotoxicity :

Not available

SECTION 13. DISPOSAL CONSIDERATIONS

1) Dispose of in a manner consistent with federal, state, and local regulations.

2) RCRA D-Series Maximum concentration of Contaminants:

Non listed

3) RCRA D-Series Chronic Toxicity Reference Levels :

Non listed

4) RCRA F-Series :

Non listed

5) RCRA P-Series :

Non listed

6) RCRA U-Series :

Non listed

Not listed as material banned from land disposal according to RCRA.

SECTION 14. REGULATORY INFORMATION

1. US FEDERAL

TSCA

CAS No. 9002-88-4 is listed on the TSCA inventory.

Health & Safety Reporting List

None of the chemicals are on the Health & Safety Reporting List.

Chemical Test Rules

None of the chemicals in this product are under a Chemical Test Rule.

Section 12b

None of the chemicals are listed under TSCA section 12b.

TSCA Signification New Use Rule

None of the chemicals in this material have a SNUR under TSCA.

SARA

Section 302(RQ)

None of the chemicals in this material have an RQ

Section 302 (TPQ)

None of the chemicals in this product have a TPQ.

Section 313

No chemicals are reportable under Section 313.

Clean air Act :

This material does not contain any hazardous air pollutants.

This material does not contain any class 1 Ozone depletory

This material does not contain any class 2 Ozone depletory

Clean Water Act :

None of the chemicals in this product are listed as hazardous substance under CWA

None of the chemicals in this product are listed as priority pollutants under the CWA.

None of the chemicals in this product are listed as toxic pollutants under the CWA.

OSHA :

None of the chemicals in this product are considered highly hazardous by OSHA.

2. European/International Regulation

European Labeling in Accordance with EC Directives

Hazard Symbols : Not available

Risk Phrases :

Safety Phrases :

S 24/25 Avoid contact with skin and eyes.

3. Canada

CAS No. 9002-88-4 is listed on Canada’s DSL/NDSL List.

WHMIS : Not available.

CAS No. 9002-88-4 is not listed on Canada’s Ingredient Disclosure List

SECTION 15. TRANSPORTATION INFORMATION

The product is not regulated by ADR/RID, IMDG or IATA

SECTION 16. ADDITIONAL INFORMATION

The information above is believed to be accurate and represents the best information currently

available to us. However, we make no warranty of merchantability or any other warranty, express or implied,

with respect to such information, and we assume no liability resulting from its use. Users

should make their own investigations to determine the suitability of the information for their particular

purposes.

Packing 25kg in aluminum and polyethylene laminated bag, vacuum inhaled stretch-wraped to prevent uptake of moisture, air and contaminants.

Container loading capacity:

|

Items |

Dimension (m) |

Door opened (m) |

Volume |

Volume (ton) |

XLPE loading volume |

|

|

With pallet |

Without pallet |

|||||

|

20FT Dry |

L: 5.90 |

L : 5.89 |

32.8~33.2 |

18~22 |

12 |

18 |

|

W: 2.34 |

W: 2.27 |

|||||

|

H : 2.37 |

H : 2.27 |

|||||

|

40FT Dry |

L : 12 |

L : 12 |

66.2~67.8 |

26~30 |

24 |

28 |

|

W: 2.23 |

W: 2.32 |

|||||

|

H : 2.35 |

H : 2.27 |

|||||

3H VINACOM XLPE HA-5010 contains all necessary components. Accordingly no premixing or preheating is required. In case of color master batch should be mixed.

3H VINACOM XLPE HA-5010 provides excellent surface without scorching over a wide temperature range. Recommendable extrusion conditions are as below.

But optimum conditions by conventional practices should be established.

|

C1 |

C2 |

C3 |

C4 |

C5 |

Neck |

Head |

Die |

|

1600C |

1700C |

1850C |

1950C |

2000C |

2050C |

2100C |

2850C |

There are various types of machines and screw type, the end users are advised to determine the optimum processing conditions by themselves.

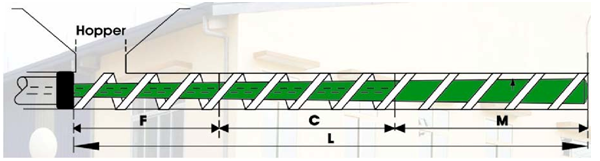

EXTRUSION EQUIPMENT

Extruder

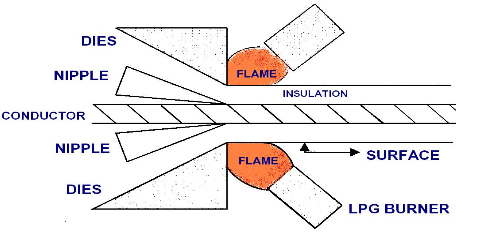

Screen pack

Gas flame

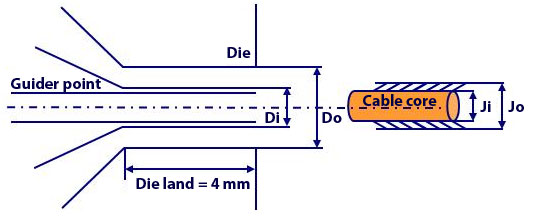

Pressure die

Tube die

Die land

HA-5010 SA can be stored for 6 months after production, at 10-30℃ in unopened original package, without significant detoriation in the quality of the material.

Avoid storage outside, water vapour absorbed.

Keep the storage out of the direct lays of the sun

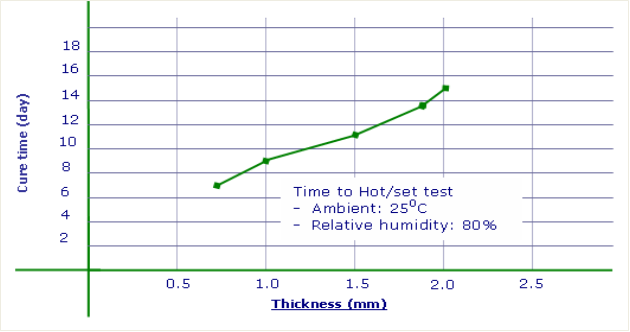

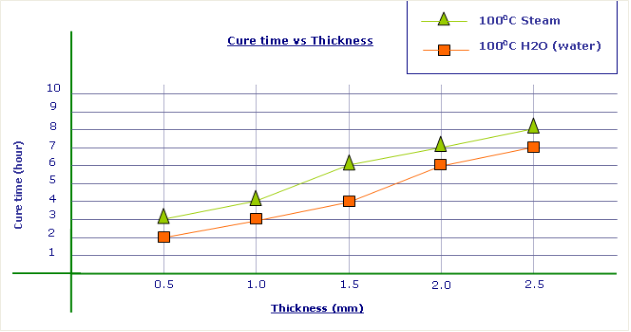

• The higher the temperature, the shorter cure time.

• Water is more effective than steam.

• Even in the air, cross-linking goes very slowly.

• From 2 to 3 weeks is necessary for cross-linking.